Pipe Vs Tube

Pipes are normally used to transport gasses or liquids making it important to know the capacity. Knowing how much can flow through the pipe is key.

Tubes are generally used in structural application and engineering components and parts.

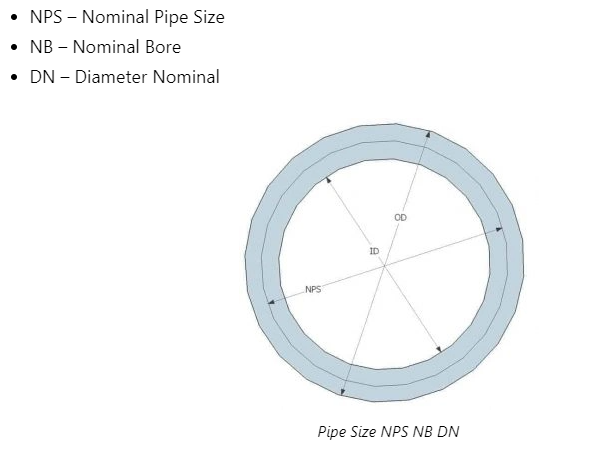

Pipe is typically ordered using the Nominal Pipe Size (NPS) standard and by specifying a nominal diameter (pipe size) and schedule number (wall thickness).

Tubes are typically ordered to outside diameter or inside diameter and wall thickness.

Tubes can come in different shapes such as square, rectangular and cylindrical, whereas piping is always round.

Pipe Dimensions

Classification of Pipe

Submerged Arc Welding (SAW) process is with filler metal welding whereas ERW/EFW and HFW are no filler welding methods to weld the pipe.

SAW pipes are further classified as straight seam and spiral seam pipe. Straight seam pipes are also known as L-SAW or long seam SAW pipes. Medium diameter straight SAW pipe has a single seam whereas a large diameter pipe has a two-weld seam.

ERW pipe manufacturing process includes HFW. ERW have low, medium, high frequency welding processes, and HFW is specially for high-frequency electric resistance welding. The differences between ERW and HFW steel pipe, is EFW (electric fusion welding) is a type of ERW process for ordinary and thin-wall thickness steel pipes.

ERW pipe: Electric Resistance Welded Pipe

HFW pipe: High Frequency Welding pipe