Various Stock Levels

Safety stock describe a level of extra stock that is maintained to mitigate risk of stock-outs. It acts as a buffer stock in case sales are greater than planned and/or the supplier take more time to deliver ordered units than its average lead time.

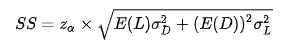

where,

- α is the service level,

- Zα =1.65 for 95% service level.

- E(L) and σL are the mean and standard deviation of lead time.

- E(D) and σD are the mean and standard deviation of demand in each unit time period.

Other easy formula for safety stock –

Safety Stock = (max. daily usages x max. lead time) – (average daily usage x average lead time)

Z × σLT × D AVG

Z is the desired service level, σLT is the standard deviation of lead time, and D avg is the demand average.

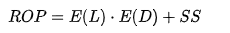

The reorder point can then be calculated as:

The reorder point is classically viewed as the sum of the lead demand plus the safety stock.

Economic Order Quantity (EOQ)

The ideal order quantity to minimize ordering cost + inventory holding costs

Q = √(2DS/H)

where:Q=EOQ units,

D=Demand in units (typically on an annual basis)

S=Order cost (per purchase order)

H=Holding costs (per unit, per year)

Min-Max Inventory – The Min/Max inventory ordering is an inventory replenishment method. The “Min” value represents a stock level that triggers a reorder and the “Max” value represents a new targeted stock level following the reorder. The difference between the Max and the Min is frequently interpreted as the EQQ (Economic order quantity – the purchase order quantity for replenishment that minimizes total inventory costs).