Strategic Sourcing Steps – 7 stages & Beyond

The concept of strategic sourcing was first introduced in 1994 by Toshihiro Nishiguchi Japanese Supply Chain Expert. He created a common strategic sourcing process based on multiple manufacturers across Japanese, German, and U.S. markets He was particularly focused Toyota Supply Chain issues.

Subsequently, Strategic Sourcing has always been a most discussed topics among Procurement Professionals. There are mainly 7 steps to successfully carry out strategic sourcing process. Once these 7 steps of strategic sourcing cycle completes, that does not mean our work is finished. Strategic sourcing is a continuous process of improvement, and Question is how to think beyond the conventional benefits and get the additional improvements.

In every profession there is two approach to achieve the goals. For attainment of short term goal tactical approaches are important, whereas for sustainable long term benefits strategic plan and actions are needed.

Strategic sourcing is proven a technique to achieve significant cost reductions and other benefits in the procurement organisation.

The 7 steps of Strategic Sourcing are-

- Category Profiling with help of Spend Analysis

- Supply Market Analysis

- Selection of Sourcing Strategy

- Request for Quotation / Proposal (RFx) to Create competition

- Negotiation and Select Vendor

- Execute Contracts & Incorporate

- Benchmarking for next Project

Before understanding the additional approach for success beyond conventional benefits of Strategic Sourcing, let us first discuss about the seven already proven steps –

Strategic sourcing – as defined by Institute of Supply Management USA, “Strategic sourcing is a supply management tool that delivers significant cost reductions and other benefits. More specifically, it’s a periodic event that includes the identification and selection of initial commercial arrangements with a selected supplier that either creates or resets a relationship.”

Let us discuss the 7 steps + 1 additional for further improvement

Step 1 – Category Profiling with help of Spend Analysis is the beginning steps of Strategic Sourcing Process

The first step of Strategic Sourcing process is to gathering purchasing data, analyzing it and building up a framework for the subsequent steps. It requires analytical skill in order to handpick useful information from company’s ERP, sometimes having lots of redundant data.

There are different ways to categorize the spend. Some examples are categorisation on the basis of direct/indirect, materials/services, domestic/import, critical/noncritical, ABC analysis, etc. However, these categories are very broad to draw meaningful conclusions and work forward, hence we may have to go into more details and assign sub-categories as well.

Categorization should be done with the long view in mind and it should not be changed frequently. If we change the categories frequently, we will not be able to compare category spend between periods.

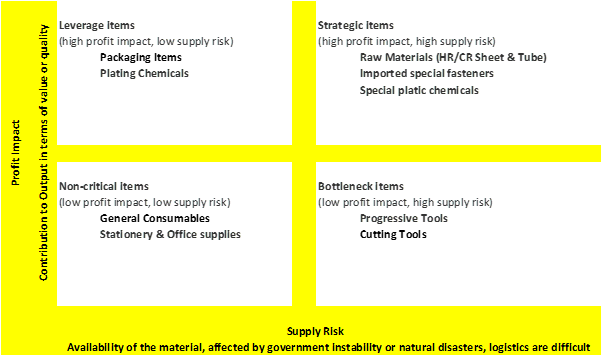

After the categorisation we need to fix the scope of our Strategic sourcing Project to go forward. Category risk analysis will help us to select & prioritise our work, where it is more beneficial for the organisation to take up strategic sourcing.

Now each category needed to analysed with help of spend analysis of historical consumption or purchase data. The spend analysis will enable us to look at the data in following different ways:

- Total spend by category and by supplier

- Top suppliers with major % of the total spend

Step 2 – Supply Market Analysis set the groundwork for all comings steps of strategic sourcing process.

The second steps of Strategic Sourcing is Supply Market Analysis. The objective of supply market analysis is to gain better working knowledge of the supplier market and position of our own company in the market place.

In this stage, we look outside of the company and start researching the supplier market. This guides us to find suppliers who could potentially provide us with the products and services we need. Low cost country sourcing should also be explored.

By the end of the supply market analysis, we shortlist suppliers to whom we will send out a Request for Proposal and sometime Request for Quotations.

We should not limit ourselves to existing suppliers only, rather we should research all suppliers. Potential new supplier may be global and local.

Need to study the cost components of the product or service, and analyse the suppliers’ marketplace for risks and opportunities. Key raw material prices and other variables such as labour and transportation must be priced and calculations done of the suppliers’ cost elements.

Step 3 – Selection of Strategy

The third steps of strategic sourcing is selection of strategy. Deciding where to buy while minimizing risk and costs is how we develop the strategic sourcing strategy.

There are many management methodologies used for strategy selection but the crust is the strategy will depend on what real alternatives there are to the current suppliers, how competitive the supplier marketplace is and importantly, how open the users are to new suppliers. Using a cross functional project team helps us to make a holistic approach towards strategy selection.

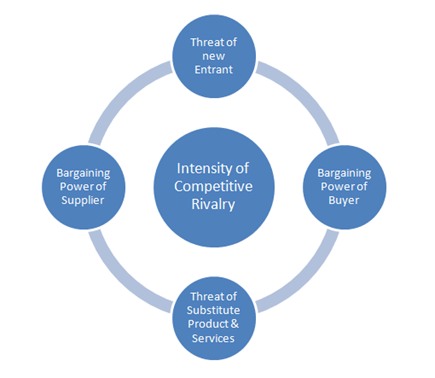

The methods those can be used are Porters Five forces & A.T. Kearney’s Purchasing Chessboard (link).

Porter described five competitive forces in his model

- supplier bargaining power,

- buyer bargaining power,

- industry internal rivalry,

- threat of new entrants, and

- threat of substitutes.

The procurement function is most interested in supplier power and buyer power. Understanding these five forces helps us to understand and evaluate competitive forces within our industry and the supplier’s industry.

We should use Porter’s method to think about and understand these competing forces every time we are preparing a strategy to use with our key suppliers.

Competitive power is also very dynamic, for example during boom times, the supplier usually has the stronger bargaining power, but during a recession, customer bargaining power is high.

To learning more about Porter’s Five Forces, check out the Five Forces tool from MindTools (link)

The Purchasing Chessboard® is another matrix with 64 fields, like a chessboard. Along the horizontal axis Buyer bargaining power is located and along the vertical axis supplier bargaining power.

To learning more about Purchasing Chessboard, check out here (link)+

Step 4 – Float RFPs to Suppliers

The fourth steps of strategic sourcing is Floating Request of Proposals or Quotations to suppliers. After creating a short list of qualified companies who could potentially become our vendors, we send them Request for Proposal. Request for Proposals is most common method of soliciting bids. All RFP must include product or service specifications, delivery and service requirements, pricing breakdown & cost analysis & legal and financial terms & conditions.

We actually challenge our existing supplier by running an RFQ/RFP process. By adding an element of competition, we leverage the RFQ/RFP to achieve cost savings and add value to the supply chain by choosing the right vendor who can meet our terms under the best conditions possible.

Step 5 – Negotiate & Select Suppliers

This fifth step is the most important step of strategic sourcing process. Two questions are to be asked during vendor selection:

- What criteria should I consider for vendor selection

- What should I look for during product qualification and site visit?

As we know The vendor lifecycle covers the entire vendor-buyer relationship, from vendor selection, then on-boarding and performance measurement, and finally ends with the off-boarding process.

The main objective of the vendor selection process is to ensure that selected vendors are good match for the buyer. The vendor selection process itself also has several important steps: vendor self-evaluation and qualification, product qualification and site visit.

After shortlisting the supplier through various screening and discussed above, negotiations are started to get most favourable terms for our organisation.

A good strategic sourcing strategy is to conduct multiple rounds of negotiations by a cross functional teams and then prepare the short list. The final selection is done by the Authorised function head and orders are awarded.

For successful negotiation tactics, please follow this link.

Step 6 – Execute & Incorporate

All supplier participated in the negotiation or discussion should be notified about the outcome of the interaction. Once a supplier is selected we need to ensure that successful suppliers execute the orders or contracts in expected manner.

Educate the new Suppliers about your company’s business practices, internal processes, regulatory essentials, and expectations for the business relationship you hope to build with them.

Procurement savings impact the companies bottom line directly.

Step 7 – Benchmark & Track Results

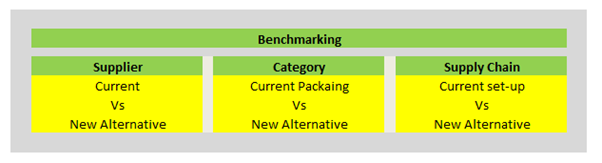

Benchmarking is one of the sourcing best practices implemented as a part of world class procurement practices. Strategic sourcing results needed to be benchmark in order to provide a more reasonable target for next projects.

As strategic sourcing is a continuous cycle, we start with benchmarking the current status of the commodity or category, monitoring the results and ensuring that full value is being achieved.

Step 8 – Moving to TVO from TCO

Once the strategic sourcing process cycle completes, that does not mean our work is finished. Strategic sourcing is a continuous process of improvement, and Question is how to think beyond the regular and get the additional improvements.

Has a periodic review with you team and see whether our strategic sourcing savings are being regularly captured and connected with your category spend?

Was it too easy to achieve initial savings? set a harder target in next strategic sourcing project.

Moving to TVO from TCO

Initially it is not that hard to bring down purchase price by running RFQs or expanding our supplier base search region. To achieve addition benefits of strategic sourcing time has come to move beyond total cost of ownership to total value of ownership (TVO) analysis.

Using TVO as a guide for sourcing process will give us numerous benefits beyond cost savings. In TVO approach we take into consideration additional value added criteria, such as ease of assembly and working efficiency etc. Let us examine the whole supply chain of the product and evaluate every operation. Analyze the value that it provides to the end customer. Operations that provide no value must be eliminated immediately. In addition to looking for ways to increase process efficiency, we must find ways to reduce supply chain risks and reduce risks to brand reputation through suppliers.

What is the 5th step of sourcing? – AnswerParadise.net

06/22/2022 at 10:21 PM[…] https://purchasinglead.com/strategic-sourcing-steps/ […]