Tool Room Materials

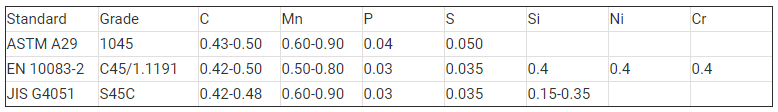

C45 [EN8 / 1045] – medium carbon steel

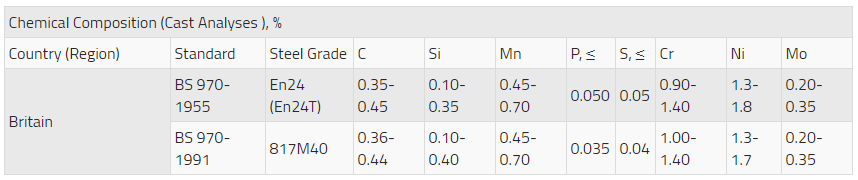

EN24 / ISO 683-18 34CrNiMo6 – high tensile alloy steel

Wear resistance, used in gears, pinions, shafts, and spindles, Die casting and hot metal processing, such as mold support, racks and gears, needle angle die casting, Hot stamping of stamping dies, aluminum and steel stamping die beds, low temperature nuts, bolts and rivets. Widely used in plastics, rubber molds, hobs and combination mold buckles, mold stop pins, etc.

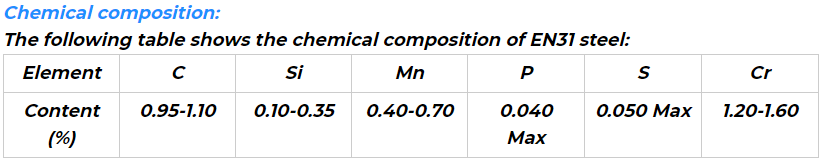

EN31 – high carbon alloy steel

Offers a high measure of hardness with compressive strength and abrasion resistance.

Typical applications for EN31 steel include taps, gauges, swaging dies, ejector pins, ball and roller bearings. It is a good quality steel for wear resisting machine parts and for press tools which do not merit a more complex quality.

H11 / H13 – Chromium Hot-Work Steels

Tool Steel H11 is a chromium-based steel alloy from the “H” family of steels according to the AISI classification system. H11 is one of the most commonly used alloys from this group, thanks to the outstanding impact toughness. Other steels from this group, such as the H13 have more vanadium, which gives better wear resistance and temper resistance, but worse impact toughness.

H13 is used in die casting mould, die casting sleeve, hot forging mould, extrusion mould and plastic mould cavity

HCHCR

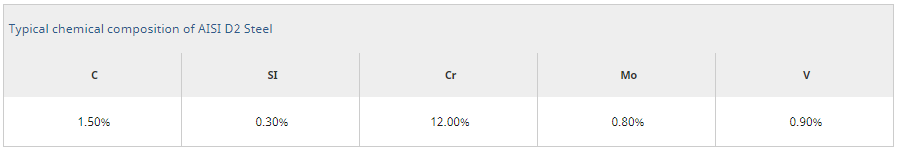

Cold-work tool steels which include D2, D3, D4, D5, and D7 steels are high-carbon, high-chromium steels. Apart from D3 steel all group D steels have 1% Mo and are air hardened.

D2 – Air hardening, high-carbon, high-chromium tool steel.

High wear and abrasion resistant. Heat treatable -hardness range 55-62 HRC.

Typical applications: Stamping or Forming Dies, Punches, Forming Rolls, Knives, slitters, shear blades, Tools, Scrap choppers, Tyre shredders etc.